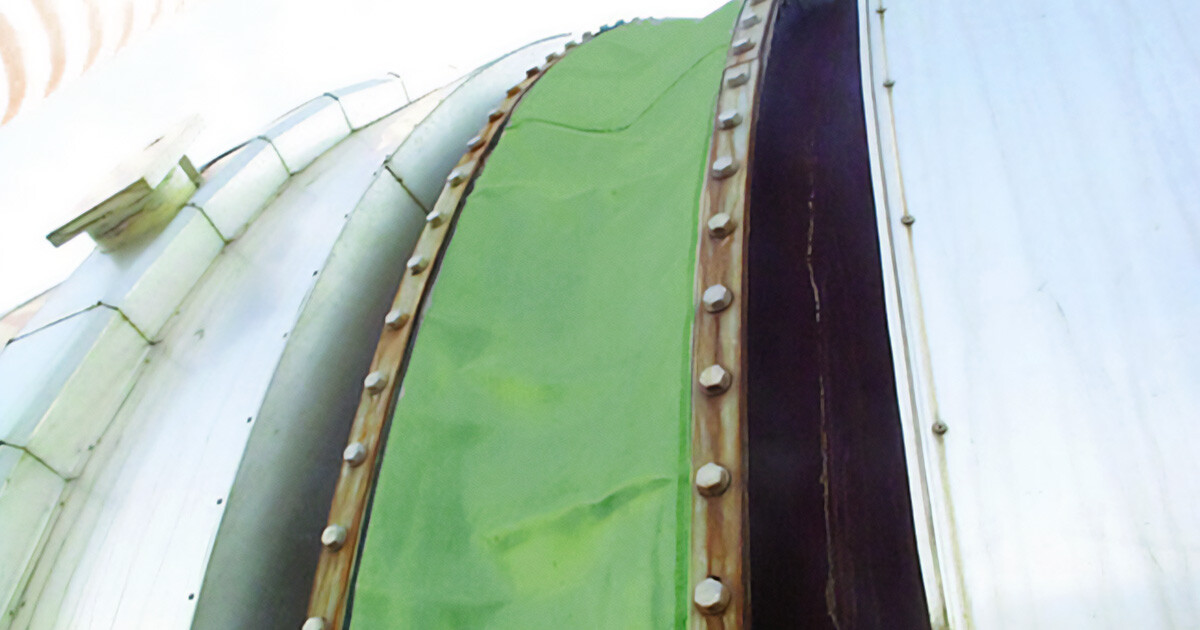

Chemically resistant protective barriers

Protection Barrier

Versiv PTFE containment liners seals in and limits the loss of vapours into the atmosphere from chemical storage tanks, while allowing for free movement of the floating roof deck.

Read More

Protection Barrier

Versiv Flueflex limits the emission of pollutants in power stations and other harsh environments.

Read More