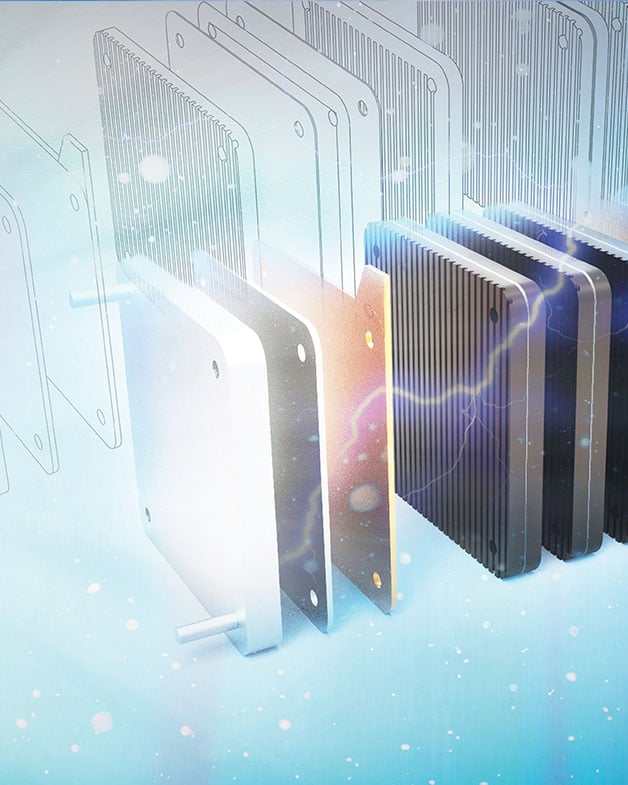

Decal substrates for fuel cell Catalyst Layer production

Problems solved:

- Thermal hysteresis

- Non-perfect wetting

- Non-perfect transfer

Applications:

- Processing aids for catalyst coating and lamination of Membrane Electrode Assemblies (MEA)

Versiv Products of Choice for Catalyst Layer Production

Features

- Low thickness tolerance

- Excellent non-stick surface

- Excellent dielectric properties

- Superior chemical resistance

- Excellent smooth surface

- Low shrinkage/hysteresis

- Excellent heat transfer

- High temperature resistance up to 260°C / 500°F

Benefits

- Improved productivity due to higher process speed

- Optimal release, allowing both wettability and release

- Low risk of creasing

- Less downtime

- Consistent production processes

- Low risk of failure due to chemical inertness

- Increased cell efficiency by thinner catalyst layers