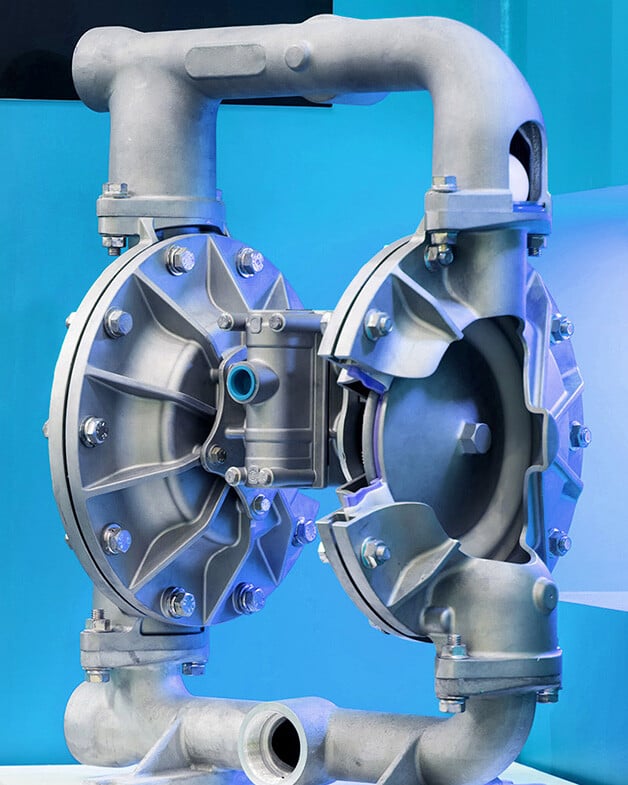

Versiv PTFE diagraphm: Ultraflex

Main benefits of Versiv Ultraflex for pump diaphragms:

High chemical resistance:

It is also resistant to hydrolysis, making it suitable for use in humid environments.

High-temperature resistance:

Flexibility and Durability:

Reduced permeation:

Versiv Ultraflex allows for both the protection of equipment and environment, and the reduction of leakage and media loss.

Smoother flow:

This leads to time, materials and energy savings through the low friction & easy release properties. It also makes them ideal for use in pumps that handle viscous or sticky fluids.