The aerospace industry values the contribution of advanced composite materials in the ongoing effort to manufacture lighter, stronger and safer aircraft. Among these, high temperature PTFE cast films meet the industry’s most stringent requirements.

Materials Fit for High-Temperature Applications

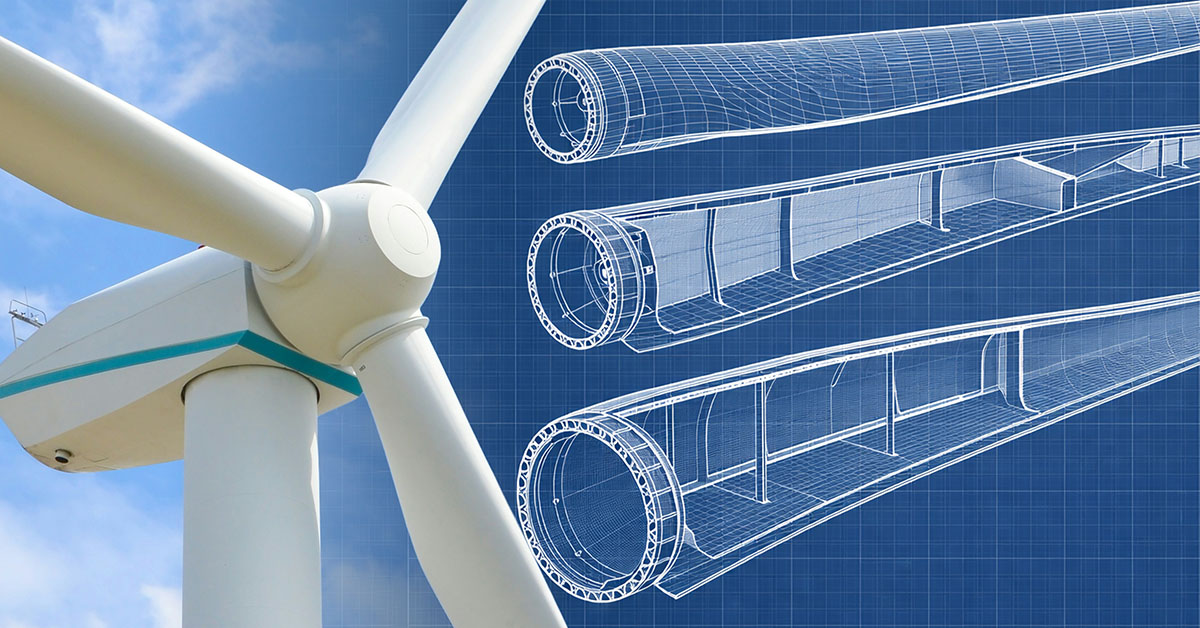

PTFE-based films are components in the vacuum bagging process that underpin aerospace composite manufacturing. The vacuum bagging process helps create high-strength, lightweight composite aircraft wing, tail and nose parts, predominantly based on carbon fibers. The technique involves using vacuum pressure to remove air and compress layers of composite materials during curing. Vacuum bag material quality directly impacts the final component's structural integrity and surface finish.

Aerospace composite manufacturing processes, such as autoclave and oven curing, routinely expose materials to temperatures exceeding 350°F (177°C), with some cycles reaching up to 500°F (260°C) or more. In these conditions, most conventional vacuum bagging films and release materials degrade, shrink, or lose their critical properties—compromising part quality and consistency.

PTFE (Polytetrafluoroethylene) cast films are engineered to withstand these extreme temperatures without sacrificing performance. Their structure ensures:

- Continuous service at temperatures up to 260°C (500°F)

- No loss of mechanical integrity or dimensional stability

- Consistent non-stick and release performance across repeated high-temperature cycles

- These properties of the material are important for the aerospace sector, as manufacturers must guarantee the structural integrity and safety of every component.

Why High-Temperature Films are Valuable to Aerospace Applications

1. Maintaining Vacuum Integrity and Preventing Defects

High-temperature PTFE films maintain their seal and structure throughout the curing process, preventing vacuum leaks, which are a leading cause of porosity voids in composites. How the materials behave under challenging heat conditions ensures that air is fully evacuated, resin properly distributed, and the resulting part is free from weak spots or bubbles.

When making a molded part, the resin, binder, or matrix should be able to flow to all areas where it is needed. Secondly, all air must be removed, as any air remaining could lead to potential failure of the finished part. This is why, when aircraft wings are produced, for example, multiple X-rays are carried out to ensure the structure is free of voids. Used to compliment the vacuum bagging films, breather or porous distribution fabrics provide channels for air to move toward the suction head placed elsewhere in the vacuum bag.

2. Reliable Release and Clean Part Removal

In terms of aircraft composite molding, the non-stick nature of PTFE, even at high temperatures, guarantees easy part release after curing. This stops damage from occurring to both the mold and the finished part, reducing downtime.

Operating in a high-temperature environment—higher than 90% of other applications— the material must withstand these temperatures without becoming brittle. After the production cycle, there must be ability to remove the part and all vacuum bagging materials in one piece.

This removability is important because, during forming and vacuum application, the bagging film and accessories conform exactly to the shape of the part. For the next part, it would be nearly impossible to place everything back in precisely the same position, especially on something as large as an 80-metre wing. The material must survive the production cycle without deteriorating or leaving any residue behind, so it can be removed cleanly and efficiently.

3. Compatibility with Advanced Resin Systems

Modern aerospace composites often use high-performance resin systems that require elevated cure temperatures. PTFE cast films are chemically inert and unaffected by aggressive chemicals, therefore minimising the potential for contamination or unwanted reactions during the curing process.

Additional Benefits of PTFE Cast Films in Aerospace

Multi-Layer Construction- Why it Works

Multilayer PTFE cast films serve to minimise voids and pinholes, and their structure compares well to conventional single-layer release films. This multi-layer composition creates robust barriers to air and moisture, further reducing the risk of defects. By creating multiple barriers against air penetration, these films prevent the formation of weak spots in the composite structure.

Flexibility of PTFE Cast Films

PTFE cast films retain their thickness, flexibility, and mechanical properties across a wide array of temperatures, ensuring uniform pressure distribution and consistent part quality.

Process Efficiency and Cost Savings

By preventing leaks and ensuring reliable release, high-temperature PTFE films reduce scrap rates, minimise rework, and make production cycles more efficient—influencing cost and time savings.

Supporting Lighter, More Efficient Aircraft

The ability to reliably produce void-free, high-strength composite components directly supports the aerospace industry’s drive for lighter, more fuel-efficient aircraft.

Meeting and Exceeding Aerospace Standards

PTFE cast films are manufactured to meet rigorous aerospace specifications and standards. Their consistent quality and traceability help manufacturers achieve and maintain compliance with industry regulations.

Conclusion

High-temperature PTFE cast films, due to their heat resistance, combined with superior release, chemical inertness, and multi-layer construction, are of high value to aircraft manufacturers. Ongoing R&D efforts in the area should make possible the development of improved next generation lightweight, high-strength, and safe aircraft components.