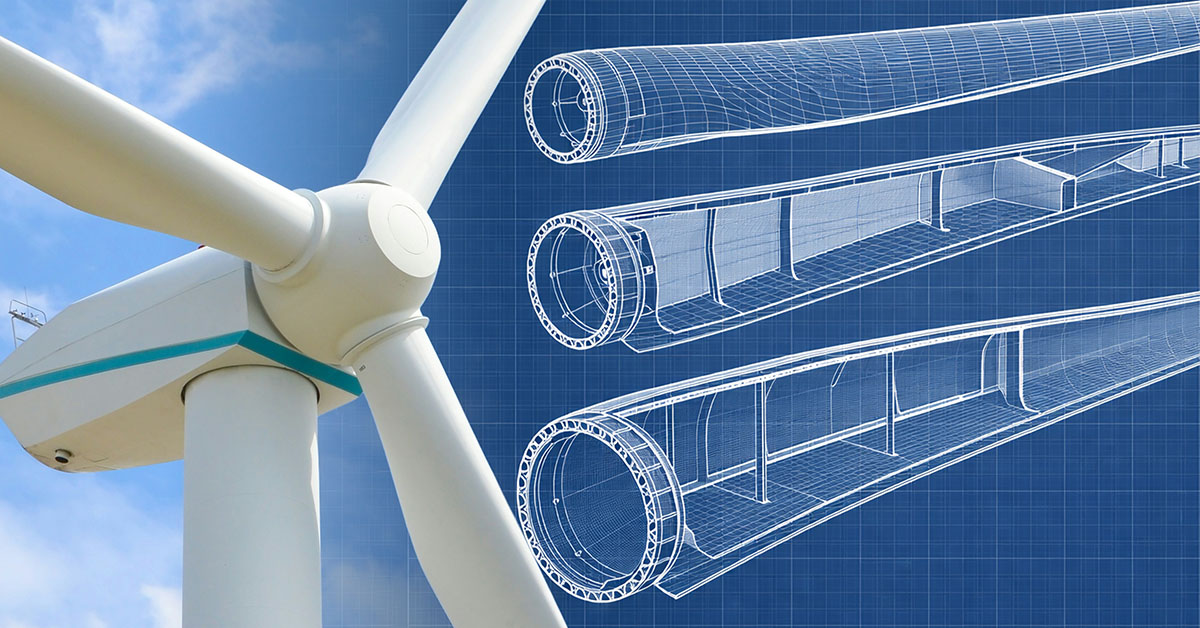

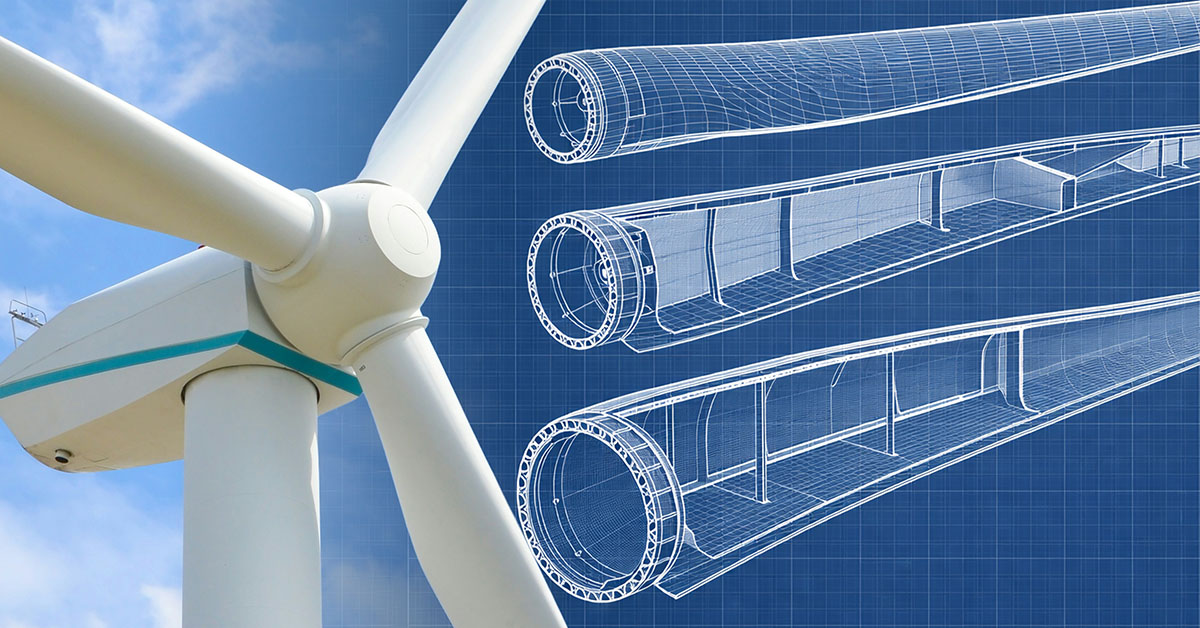

Modern wind blades are becoming significantly larger, requiring advanced designs that reduce structural loads while maintaining long-term durability. As the market expands, our PTFE adhesive tape systems continue to evolve to satisfy the needs from wind turbine blade manufacturing processes.

Wind turbine blades are typically produced via composite moulding, a process that allows for large scale, geometry complexity and repeatability.

The process starts with a precision mold that defines the blade’s aerodynamic shape. Layers of fiberglass or carbon fiber reinforcements are placed into the mold according to the structural design, followed by resin infusion or application to bond the materials. The blade is then cured under controlled conditions, demoulded, and finished through trimming, bonding of blade halves, and surface treatments to produce a lightweight, high-strength structure designed for long-term operation.

PTFE Mould Release: A substitute for wax and spray

Resins can chemically and mechanically adhere to the mold during curing, making part removal difficult and risking damage to both the component and the tool. Release agents create a temporary barrier that allows the part to separate cleanly from the mold after curing.

Challenges arise as typical solutions such as wax and spray release agents require frequent reapplication and cleanup between pulls, increasing downtime and labor costs. Buildup and overspray can contaminate mold surfaces, leading to inconsistent release performance and surface defects.

Versiv PTFE Adhesive Tape Systems offer a cleaner and longer lasting alternative to wax and sprays in the production of wind blades.

Composed of PTFE impregnated fibreglass fabric + silicone pressure sensitive adhesive, these materials ensure an easy removal of the moulded components with no transfer of resins. They also allow for more pulls prior to cleanup, with reduced risk of buildups or inconsistent coverage.

After demoulding operation is finished, Versiv’s specially formulated, high temperature and sheer resistant pressure sensitive adhesive allows for an easy, residue-free removal.

Key benefits of Versiv PTFE for moulding release:

- Resistance to epoxy and molten thermoplastics

- Up to 60 pulls*

- Controlled texture for optimal postprocessing

- Chemically inert and temperature resistant

- Flexible and mechanically stable

- Wear resistant and durable

- Easy demoulding operation

- Controlled texture for optimal postprocessing

- Proven long life solution

- Suitable for all blade sizes

*In a regular impact area

Products of Choice

All materials contain silicone pressure adhesive added to one side.

Lightly textured PTFE coated fabric. High flexibility.

Lightly textured PTFE coated fabric. High flexibility.

Smooth PTFE laminated product with superior release and extended durability. Highest flexibility and ease of use.

Smooth PTFE laminated product with superior release and extended durability. Medium flexibility.

Versiv PTFE solutions help manufacturers improve efficiency, surface quality, and reliability—supporting the next generation of wind energy innovation.